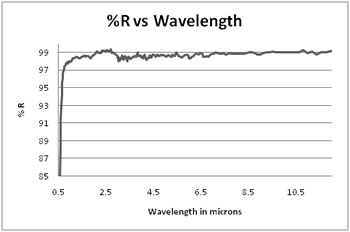

Electroplated Gold coating has excellent and consistent reflectivity in the infra red, and good reflectivity in the visible, which allows the easy use of red alignment lasers. Unlike vacuum deposited Gold coatings, electroplated Gold never peels, flakes, or delaminates.

Electroplated Gold coating has excellent and consistent reflectivity in the infra red, and good reflectivity in the visible, which allows the easy use of red alignment lasers. Unlike vacuum deposited Gold coatings, electroplated Gold never peels, flakes, or delaminates.

Polarization changes on reflection are virtually zero, so for metal cutting and other polarization sensitive applications, gold mirrors are the most reliable way of maintaining polarization. Because reflectivity is almost independent of angle of incidence, Gold is an excellent choice of coating for scanner mirrors, or mirrors used off axis.

Electroplated Gold coating is in intimate thermal contact with the mirror base, so localized burns, dust, and scratches from high power lasers have little effect on the mirrors performance.

Electroplated Gold is widely used with Er:YAG lasers, CO2 lasers, QCL’s, OPO’s, and many other applications in the infra red 1-100um spectrum.

Our Gold coating covers all the mirror surfaces, front sides and rear, so there are no discontinuities that can initiate delamination of the coating. Cassegrain reflectors, and Herriott cells use gold coated metal mirrors for the benefit of the through holes in the mirror are also coated.

Chemically deposited Gold coating has a huge laser damage threshold and with a copper mirror base will withstand 40 KiloWatts, see laser damage resistance of CO2 laser optics

Gold mirrors need careful cleaning, see our technical documents on the subject of cleaning laser mirrors and contamination.

A survey of used MaxR coated mirrors from different suppliers has shown that most mirrors after just a short time of use, regardless of reflectivity when new, are typically 98% Reflective.