MAX R for 10.6 microns

High reflectivity coatings for CO2 lasers are made on, copper, silicon or aluminum mirrors. Uncoated metals such as copper and gold, have excellent broad reflectivity in the infra red, and useful reflectivity in the visible as well. There are occasions when even tiny losses are a problem (such as as cavity fold mirrors), and an enhanced coating is needed.

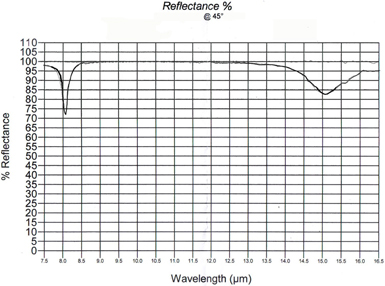

Beam delivery optics used outside the resonator, such as in flying optics cutting systems, can use enhanced mirror coatings to reduce losses on reflection: A series of thin film, high and low refractive index materials are deposited onto the polished substrate in a vacuum coating chamber. This can enhance the reflectivity at the specified wavelength, and angle of incidence, to greater than 99.8%. Such high levels of reflectance, needs sophisticated calorimetric measurement to ensure specifications are met.

EOC offers enhanced metal reflectors for standard wavelengths such as 10.6 microns. Other coating properties such as reflective phase retarders for circularly polarizing a laser beam, or dual band coatings that are reflective at two different wavelengths at the same time eg CO2 and HeNe, are possible.

Our MaxR coating offers excellent resistance to the darkening effect of UV radiation in gas laser discharges. MaxR coating is available on either copper or silicon substrate mirrors. Water cooling is recommended for resonator mirrors, and water cooled copper mirrors are the product of choice for high power fold optics….see Thermal Behavior of CO2 laser optics.