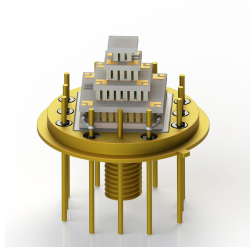

If you are looking for quality and reliability for your thermoelectric (TEC) requirements, then i-TEC has the solutions for you. With more than 3,000 high quality and reliable single and multistage micro-TEC models, this is the widest range of thermal, electrical and mechanical properties available.

Options include substrate material, inner solder, cold and hot side metalization, type of lead wires, etc. We also provide mounting of the micro-coolers to the different types of headers, sockets, and housings.

i-TEC’s micro-TECs are used for thermal management of the key components in various high-value and high-tech products which usually work in harsh conditions. Achieving the highest reliability of the thermoelectric products is a fundamental concept for them. i-TEC performs a whole range of tests for compliance with world quality standards. All i-TEC products are Telcordia GR468 and MIL-STD -883 compliant.

Standard Products

Flexible Individual Solutions – Custom Products

Development Products – R&D Capabilities

Applications

Flexible Individual Solutions – Custom Products

i-TEC can produce micro-TECs with nonstandard combinations of thermoelectric dices cross sections, height, pitch, connection, etc. They have flexibility in finding the optimum thermoelectric solutions for you and can easily provide identical replacement of any micro-TEC model previously used.

Custom Micro-TECs Options

All micro-TECs can be produced to the wide range of standard manufacturing options such as:

- Ceramic material

- Inner solder

- Cold and hot side mentalization

- Type of lead wires

- Installation of the own micro-coolers on different types of headers, sockets, and housings.

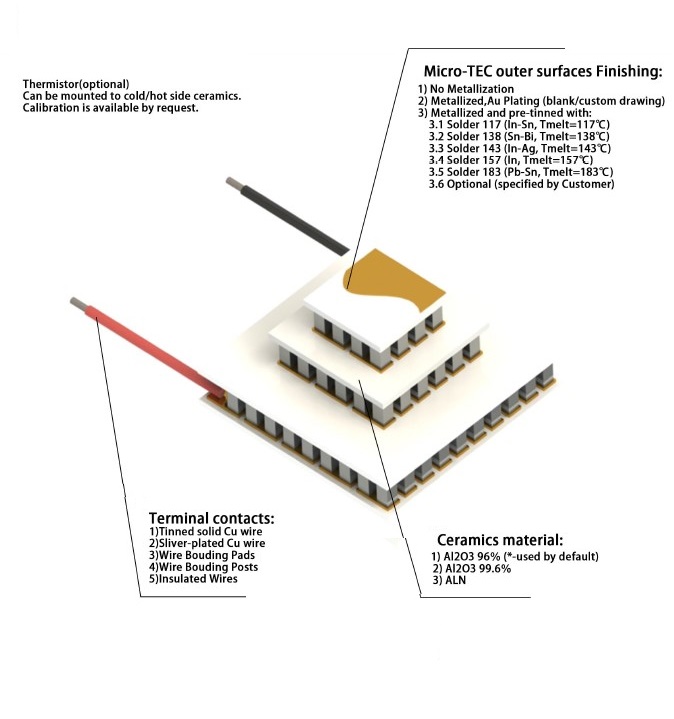

Thermistor (location optional)

TEC Outer Surface Finishing (see many options on diagram below)

Terminal Contacts (see 5 options on diagram below)

Ceramic Materials (see 3 options on diagram below)

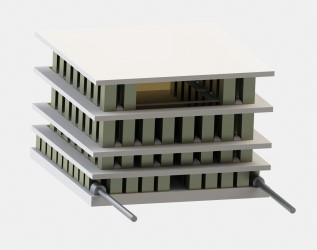

Development Products – R&D Capabilities

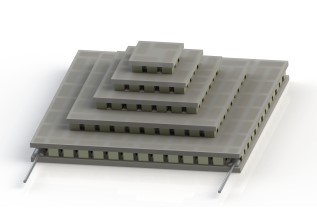

Development and R&D capabilities include:

- The minimum size 1mm*1mm – state of the art technology

- 7 Stages

- The maximum temperature difference 160℃ (Th = 30℃, vacuum, no heat load)

- Customized TEC design:

Circle, center hole

Custom TO package installation

Applications

Cooling and Temperature Stabilization

IR (InfraRed) Detectors

- Infrared exploration satellite

- Free space optical communication

- Non-contact temperature measurement

- Spectral analysis

- Air pollution and water quality monitoring

- Gas analysis and detection

- Laser power control and calibration

- Smart ammunition

Silicon Drift Detectors

- X-ray fluorescence spectrometry

- Scanning electron microscope

- Space instrument

- Nuclear power

CCD/EMCCD/CMOS/sCMOS Cooling

- Quantum Entanglement

- Ultracold Quantum Gases, BEC & Trapped Ions

- Wavefront Sensors (Adaptive Optics)

- Speckle Imaging and High-Speed Astronomy

- Guide Cameras

- Fast Hyperspectral Imaging

Lasers & Laser Diodes

- Flammable and explosive gas concentration monitoring

- Toxic gas concentration monitoring (sulfur dioxide, HF)

- NIR and MIR lasers (Infrared Detection)

- Laser guidance

- Breathing gas detection (oxygen, carbon oxide, methane, Nitrogen oxide)

- Optimization of automotive engine combustion efficiency

- Martian Soil Detection and Analysis (Isotope Detection)

- Spaceship fire and explosion prevention

Lasers for Communications

- Optical modules

- TOSA

- ROSA

- BOSA

- Optical amplifiers – (Maintain the stability of the operating wavelength)

- Ensure device performance

- Heat dissipation of high-power devices

Polymerase Chain Reaction (PCR)

- TEC can switch between cooling and heating by changing the current direction, which is especially suitable for applications where PCR requires both heating and cooling (cooling).

- TEC can adjust the cooling capacity of TEC by changing the current to achieve accurate temperature control.

- TEC has no vibration, no noise, no pollution in the working process.

- The TEC commonly used in PCR is small and medium size and micro single-stage TEC.

- PCR application conditions have high requirements on the cold and hot cycle life of TEC.

- Each PCR machine usually uses multiple TECs.