- High temperature resistance

- Increased durability, high strength, hermetically sealed

- Possibility of soldering, embedded fibers, bundles, pigtails, inlets to high vacuum

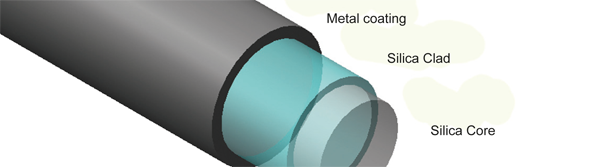

art photonics Metal-Coated Silica Fibers are ideally suited for use in high temperature, vacuum and harsh chemical environments. This is due to the strong mechanical adhesion of the metal directly to the silica cladding during drawing process.

Applications:

- High temperature environments

- Harsh Chemical environments

- Nuclear radiation

- High Power Laser delivery

- Medical applications

- Soldered fiber bundles

| FlexiRay® MCS | Specification |

|---|---|

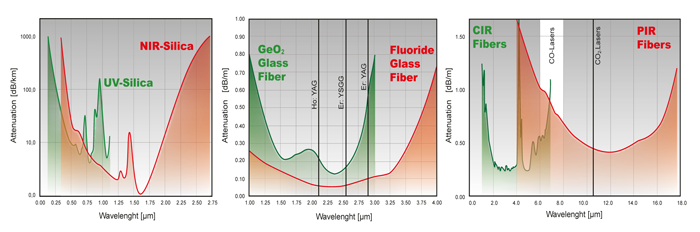

| Core material | Pure silica High OH- ( λ= 0.18 – 1.2 µm) Low OH- ( λ= 0.35 – 2.5 µm) |

| Cladding material | Fluoride doped fused silica |

| Standard Numerical Aperture (NA) | 0.22 ± 0.02 (Full Acceptance Angle 25°) |

| Available Numerical Aperture (NA) | 0.12 ± 0.02 (Full Acceptance Angle 14°) 0.26 ± 0.02 (Full Acceptance Angle 30°) |

| Material of metal coating | Al, Cu |

| Humidity Range | Up to 100% |

| Minimal bending radius (long term) | 200 x fiber outer diameter |

| Minimal bending radius (short term) | 100 x fiber outer diameter |

| Coating material | Al | Cu-alloy |

|---|---|---|

| Standard Fiber core diameters, µm | 9 200 400 600 1000 | 9 200 400 N/A N/A |

| Coating thickness, µm | 15 - 150 | 15 - 150 |

| Min operating temperature, °C | -270 | -270 |

| Max operating temperature, °C | 400 | 600 |

| Tensile strength (short gauge), GPa | 3.5 – 6 | 2 – 3 |

| Two point bending strength, GPa | >10 | >10 |

| Static fatigue parameter | >100 | >100 |